Thin-film solar panels stand at the forefront of renewable energy technology, offering innovative alternatives to conventional photovoltaic systems. Characterized by their light weight, flexibility, and adaptability, these panels form an intriguing topic for exploration. With their ability to harness solar energy under varied lighting conditions, thin-film variants like cadmium telluride and copper indium gallium selenide present distinct advantages, particularly in settings where traditional panels falter. The complex manufacturing processes and continuous research efforts to enhance their efficiency suggest a dynamic evolution. What role do these advancements play in shaping future energy solutions?

Expert Highlights

- Thin-film solar panels offer a lightweight and flexible design, allowing versatile installation options and reduced structural reinforcement needs.

- Efficient manufacturing processes make thin-film panels cost-effective, with production costs around £0.80 per watt.

- These panels perform well in low-light conditions and have a low temperature coefficient, enhancing performance in heat.

- Thin-film solar technology includes various materials like CdTe, CIGS, GaAs, and a-Si, each offering unique efficiency and cost benefits.

- Innovations like roll-to-roll processing and inkjet printing optimize production for better efficiency and cost-competitiveness.

Thin-Film Solar Technology

Thin-film solar technology encompasses a variety of types, including cadmium telluride (CdTe), copper indium gallium selenide (CIGS), and amorphous silicon (a-Si), each with distinct manufacturing processes that influence their efficiency and cost profiles. These panels are notably thinner and flexible, allowing them to be versatile in application and installation. The deposition techniques used in producing these panels can range from sputtering to chemical vapor deposition, requiring specialized equipment and expertise. Understanding these processes is critical for evaluating the balance between production costs and energy conversion efficiencies in thin-film solar panels.

Types of Thin-Film

When exploring the various types of thin-film solar technologies, several distinct options stand out due to their unique characteristics and advantages. Cadmium Telluride (CdTe) is prominent for industrial applications but raises toxicity concerns. Researchers at MIT have taken strides in developing ultralight fabric solar cells that can be seamlessly integrated into various objects. Amorphous Silicon (a-Si) offers cost-effectiveness and flexibility. Copper Indium Gallium Selenide (CIGS) is remarkable for its flexibility and environmental tolerance, while Gallium Arsenide (GaAs) excels in efficiency but is costly.

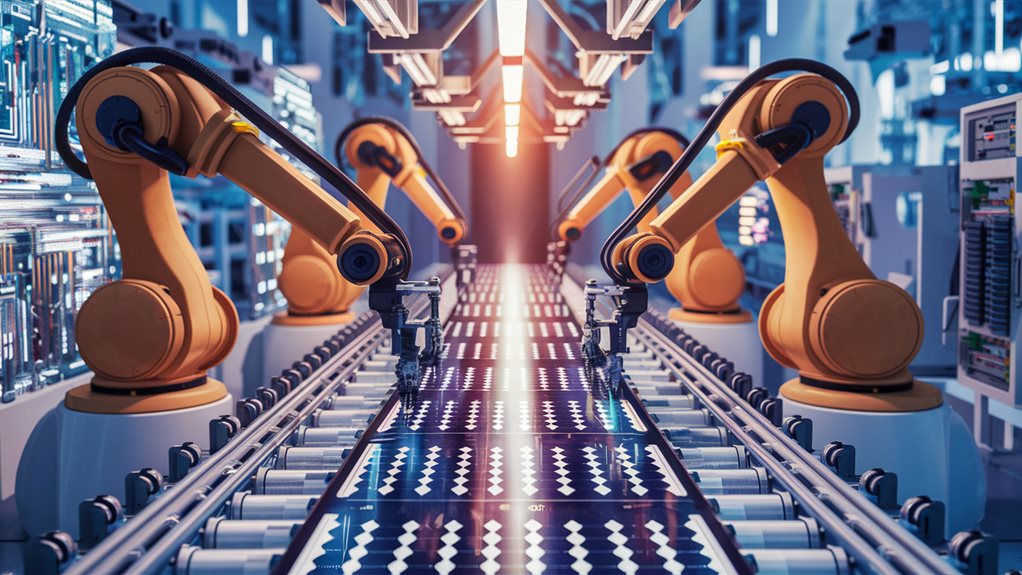

Manufacturing Processes Explained

Manufacturing processes for thin-film solar technology commence with the meticulous preparation of Transparent Conductive Oxide (TCO) glass, a critical component in the assembly of solar cells. TCO glass undergoes a sequence of steps:

- Trimming to guarantee safety by reducing sharp edges

- Cleaning to remove contaminants with deionized water

- Laser cutting for precise scribing

- Re-cleaning post-scribing to eliminate residues

- Preheating before deposition processes

Thin-film amorphous silicon solar cells are produced through research and development, leveraging large batch and single chamber deposition techniques to ensure efficiency in preparation stages.

Efficiency and Cost Factors

Efficiency and cost considerations are pivotal when evaluating thin-film solar technology. Thin-film panels, with efficiencies between 6% and 18%, vary based on semiconductor materials like CdTe and CIGS. Due to advancements in manufacturing techniques, photovoltaic materials used in thin-film panels are applied in layers just a few micrometers thick, which enhances flexibility and reduces material costs. Manufacturing costs remain lower than crystalline silicon, around £0.80 per watt, though larger areas are needed for equivalent power output. Their low temperature coefficient enhances performance in heat, making them ideal for expansive commercial projects.

Benefits

Thin-film solar panels offer significant advantages, including a lightweight and flexible design that enhances installation versatility across diverse applications, from rooftops to portable devices. Their production involves lower energy costs, which contributes to making these panels a cost-effective solution. Additionally, the temperature sensitivity of such panels is a consideration, as performance can decrease at higher temperatures. Moreover, their improved performance in low-light conditions guarantees reliable energy output even in less favorable settings, reducing installation intricacy and widening deployment potential.

Lightweight and Flexible Design

Where traditional solar panels are limited by their bulk and rigidity, thin-film solar panels excel with their lightweight and flexible design, offering numerous benefits.

These panels use less material, enhancing portability and ease of installation. They adapt to various surfaces, allowing integration into diverse architectural applications. Recent advancements in thin-film solar technology have enabled the development of transparent solar windows and solar-powered wearables, expanding the potential applications of these panels even further.

- Minimal material usage for sustainable manufacturing

- Seamless portability for mobile applications

- Effortless installation on diverse surfaces

- Architectural integration for energy-efficient buildings

- Versatile adaptation for unique environments

Lower Energy Production Costs

A compelling advantage of thin-film solar panels lies in their ability to markedly reduce energy production costs. Their production is less expensive due to reduced material usage and a simplified manufacturing process, which involves fewer steps and less energy consumption. Thin-film solar cells utilize less semiconducting material than traditional solar panels, resulting in thinner sheets that can be produced at a lower cost. These factors result in lower material and labor costs, making thin-film solar panels a cost-effective alternative for energy production, with promising long-term financial benefits.

Improved Performance in Low Light

Amidst the advantageous cost reductions offered by thin-film solar panels, their improved performance in low-light conditions further enhances their appeal. These panels absorb a broader sunlight spectrum, even in weak light, thereby generating power in less-than-ideal lighting. Thin-film solar panels can perform effectively on cloudy days, as they efficiently absorb diffused, infrared, and ultraviolet light that penetrate the clouds.

- CIGS and CdTe: Broader absorption range

- Performance: Early mornings, late afternoons

- Reliability: Cloudy, rainy conditions

- Versatility: Flexibility in applications

- Efficiency: Stable in varied light

Reduced Installation Complexity

Due to their inherent design advantages, thin-film solar panels considerably reduce installation complexity, offering numerous benefits that make them an appealing option for various applications. These panels require less labor and fewer materials, simplifying mounting systems. Unlike mono/poly-crystalline panels, which use thicker materials, thin-film solar panels utilize less material overall, making them lighter and easier to handle during the installation process. Their light and flexible nature facilitates quick installation, particularly in unconventional spaces. Consequently, reduced installation costs and structural reinforcement needs result in significant time and cost savings, enhancing their market competitiveness.

Manufacturing Process Innovations

In the domain of thin-film solar panels, manufacturing process innovations are reshaping production through the integration of advanced materials, cost-effective methods, and enhanced efficiency techniques. Novel materials such as perovskites and bifacial CdTe modules are being utilized to push efficiency boundaries, while scalable production techniques like roll-to-roll processing and inkjet printing substantially lower costs. Thin-film technology is known for its better performance in low-light conditions and high temperatures, consistent energy production throughout the day, and reduced material consumption. The following table highlights key innovations in materials, processes, and efficiency strategies, bringing these solar technologies closer to widespread adoption.

| Category |

Innovation |

Impact |

| Material Usage |

Perovskite materials |

Higher theoretical efficiencies |

| Production Method |

Roll-to-roll processing |

Scalable and cost-effective |

| Efficiency |

Multi-junction cells |

Improved energy conversion |

| Cost |

Inkjet printing |

Reduced manufacturing expenses |

| Integration | Energy storage solutions | Enhanced performance and reliability

Advanced Material Usage

Several advanced material manufacturing processes have been developed to enhance the efficiency and reduce the cost of thin-film solar panels. These innovations utilize cutting-edge techniques and materials to improve solar power performance sustainably.

- Vapor-transport deposition for precise material application

- Close-spaced sublimation for uniform layer distribution

- 高throughput computational screening for new materials discovery

- Zintl-phosphide research for innovative absorbers

- Perovskite exploration for tandem technologies

Cost-Effective Production

Building on the advancements in advanced material usage, the path toward cost-effective production of thin-film solar panels is equally marked by significant innovations in manufacturing process techniques.

Researchers are exploring new deposition methods and material alternatives, enhancing scalability and efficiency. Automation, improved encapsulation techniques, and reduced capital costs for equipment and facilities contribute to lower production costs, positioning thin-film technology as an increasingly competitive option in solar energy markets.

Efficiency Enhancement Techniques

Optimizing the efficiency of thin-film solar panels remains paramount within the sphere of renewable energy advancements. Manufacturing innovations such as the ASTL method and USSC coating enhance CIS efficiency by integrating alkali metals.

Flexible ceramic sheets increase durability, while perovskite/CI(G)S tandem structures yield high efficiency. Sustainable production minimizes energy and material usage.

- ASTL deposition method

- USSC & SoS coating

- Ceramic sheet flex durability

- Perovskite/CI(G)S integration

- Sustainable production practices

FAQ

How Long Do Thin-Film Solar Panels Typically Last?

Thin-film solar panels typically last between 10 to 20 years. Despite a shorter lifespan compared to other solar panel types, they offer reduced manufacturing costs and quicker payback periods, often proving advantageous in specific applications.

What Are the Installation Costs of Thin-Film Solar Panels?

Installation costs for thin-film solar panels typically range from $10,000 to $20,000 for a 5 kW residential system, varying by technology, location, and additional components like inverters, which range between $1,000 and $3,000.

Can Thin-Film Solar Panels Be Recycled?

Yes, thin-film solar panels can be recycled. The process involves shredding, material separation, and chemical dissolution to recover up to 95% of semiconductor materials and 90% of glass, enabling sustainability and reducing environmental impact.

Are Thin-Film Solar Panels Effective in Low-Light Conditions?

Thin-film solar panels are effective in low-light conditions due to their superior performance and stability. They maintain consistent power output on cloudy days and at dusk, making them suitable for diverse weather environments and specific applications.

What Are the Main Environmental Impacts of Thin-Film Solar Panel Production?

The production of thin-film solar panels poses environmental challenges, including heavy metal toxicity, habitat destruction, significant energy consumption, and chemical pollution. Addressing proper recycling and eco-friendly manufacturing could mitigate these impacts, promoting sustainable energy solutions.

Experts Final Thoughts

Thin-film solar panels, with their diverse semiconductor materials and adaptable manufacturing processes, present a promising alternative to traditional solar technologies. The panels' lightweight and flexible nature, combined with satisfactory performance in low-light conditions, enhances their applicability in various scenarios. Continuous advancements in manufacturing processes and material usage contribute to improved efficiency and cost-effectiveness, strengthening their competitive position in the renewable energy market. As research progresses, thin-film solar panels are poised to play an increasingly significant role in sustainable energy solutions.